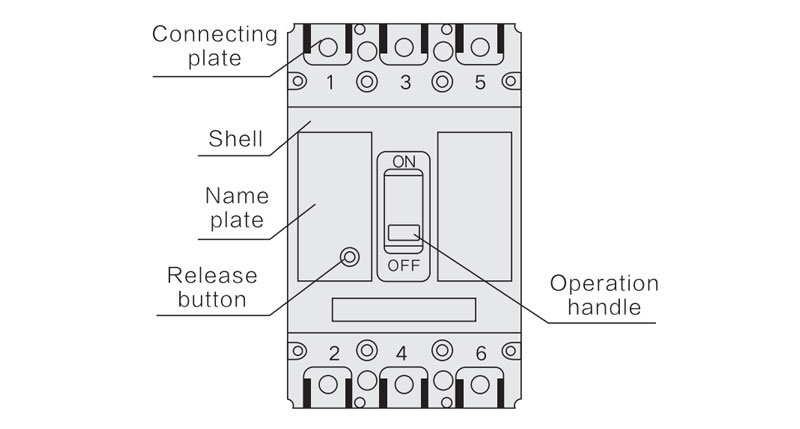

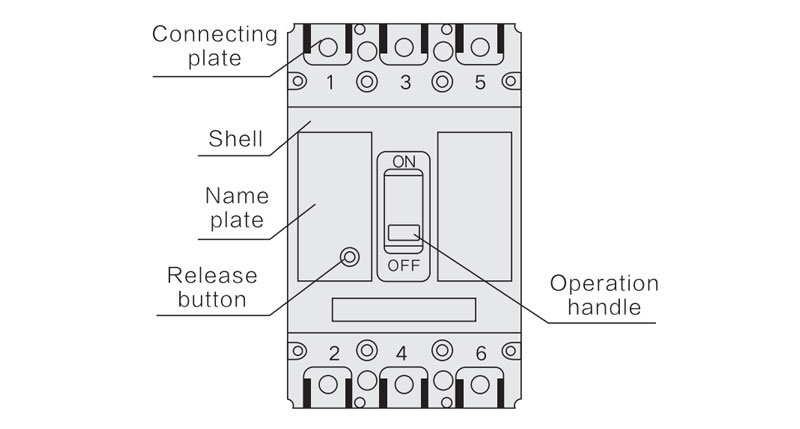

The appearance of the product and the name of the parts

Storage environment

| ltem |

Specification |

| Ambient temperature |

-25℃~+55℃ |

| Relative humidity |

(When the environmenttemperature is 25) ≤95% |

lnstallation

Insulation test

According to the standards, the circuit breaker need to take the insulation test before out of factory. Because the circuit breaker has the electronic circuit boards. lf you want to retest, must according tothe following steps:

a. use 1000VDC megger.(M3-63, use 500VDC)

b. lnsulation resistance should be not less than 20MQ.

d. Link the under-voltage release of circuit breaker to the inputline and the shell.

lf the users do not have megger, can replace it with frequencyvoltage tester.add voltage 2000Vlmin.

Using environment

The environmental requirement where the circuit breaker install

| Ambient temperature |

-5℃~+40℃,and average of 24h is not morethan 35℃. |

| Relative humidity |

When the temperature is 40℃, do not morethan 50%, in the most wet month,

the averagecan not higner than 25℃,

and also the biggest average relative humidity can not more than 90 %,

thinking the change of the temperature when the frost on surface of the products |

| Altitude |

No more than 2000m |

| Pollution |

3 Class |

Tripping characteristics of switching MCCB

| Rated current of release (A ) |

Thermodynamic release (ambient temp 40℃ ± 2℃) |

Operational current of magnetic release (A) |

| 1.05In (Cold state) inoperative time(h) |

1.3In (Cold state) inoperative time(h) |

| ln≤63 |

≥1 |

<1 |

10ln ± 20% |

| 63≤ln≤250 |

≥2 |

<2 |

| 250≤In≤800 |

≥2 |

<2 |

5In ± 20%10

In ± 20% |

Notes: The instantaneous action value of the rated operating current ln=10A-40A ofthe circuit breaker is the same as that of ln=50A

Tripping characteristics of overload protection MCCB

| Rated currentof release (A) |

Thermodynamic release (ambient temp 40℃) |

Operational current of magnetic release(A) |

| 1.0In (Cold state) inoperative time (h) |

1.2In (Cold state) inoperative time (h) |

1.5In (Cold state) inoperative time (h) |

7.2In (Cold state) inoperative time (h) |

| ln≤250 |

≥2 |

<2 |

<4min |

4s<Tp≤10s |

5ln±20%

10ln±20% |

| 250≤ln≤630 |

<8min |

4s<Tp≤20s |

Notes: The instantaneous action value of the rated operating current In=10A-40A of the circuit breaker is the same as that of ln=40A

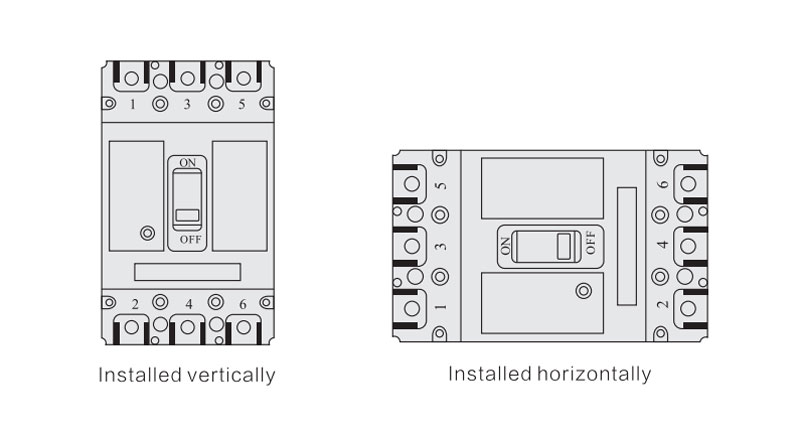

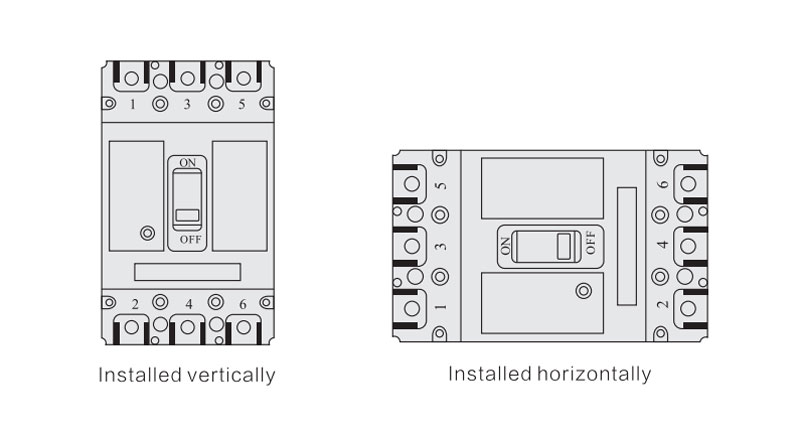

Installation method

Circuit breaker can be installed vertically, but also horizontally

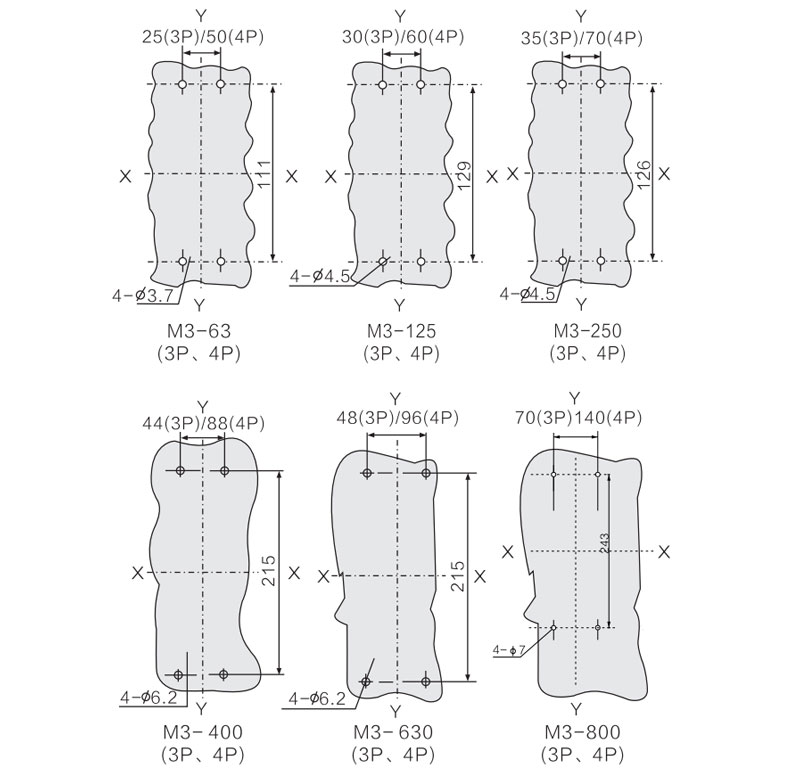

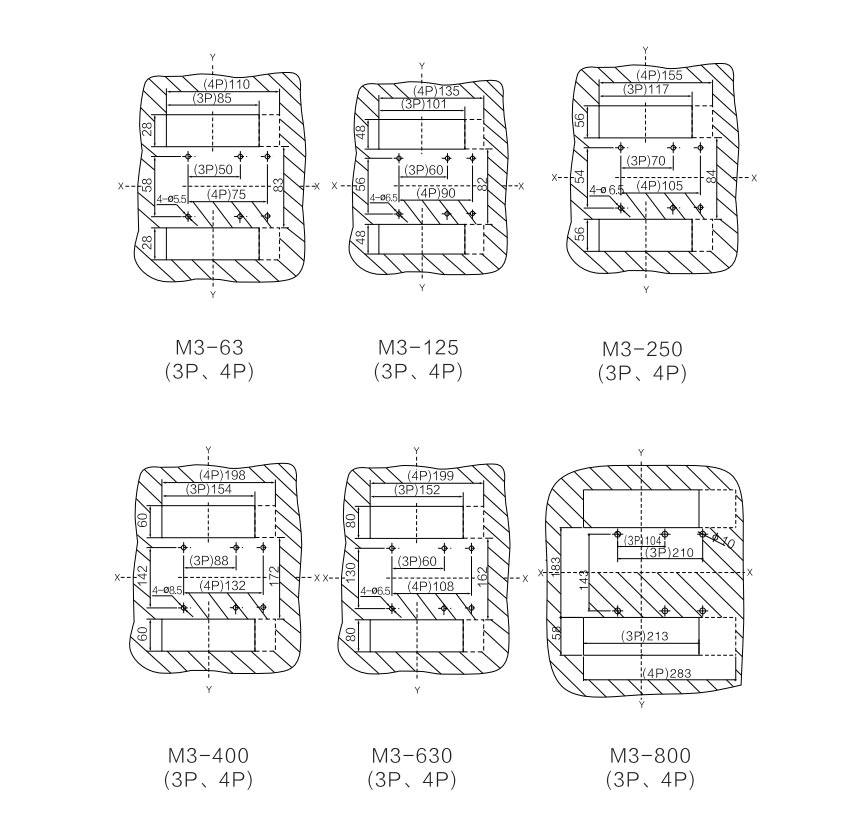

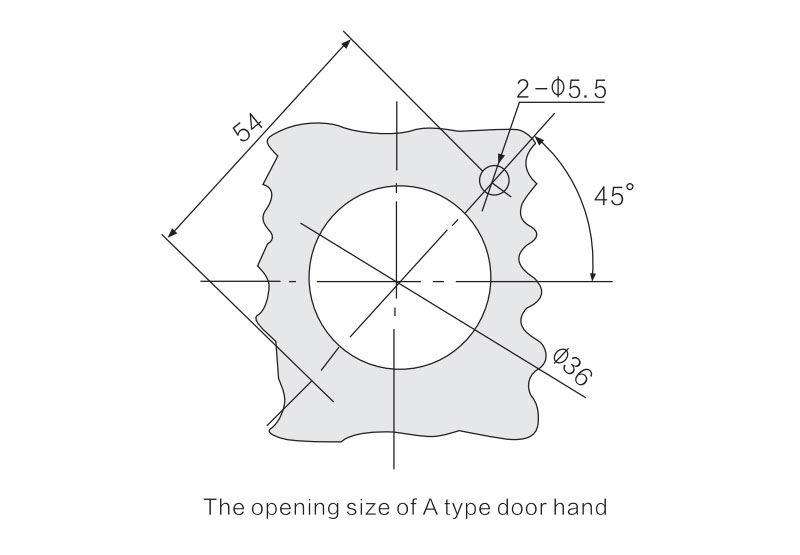

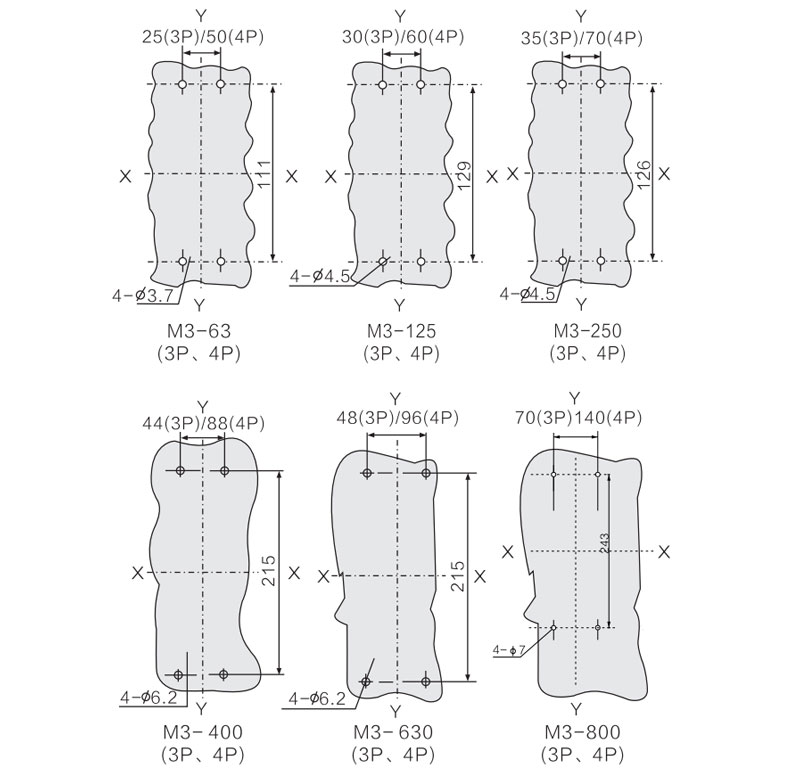

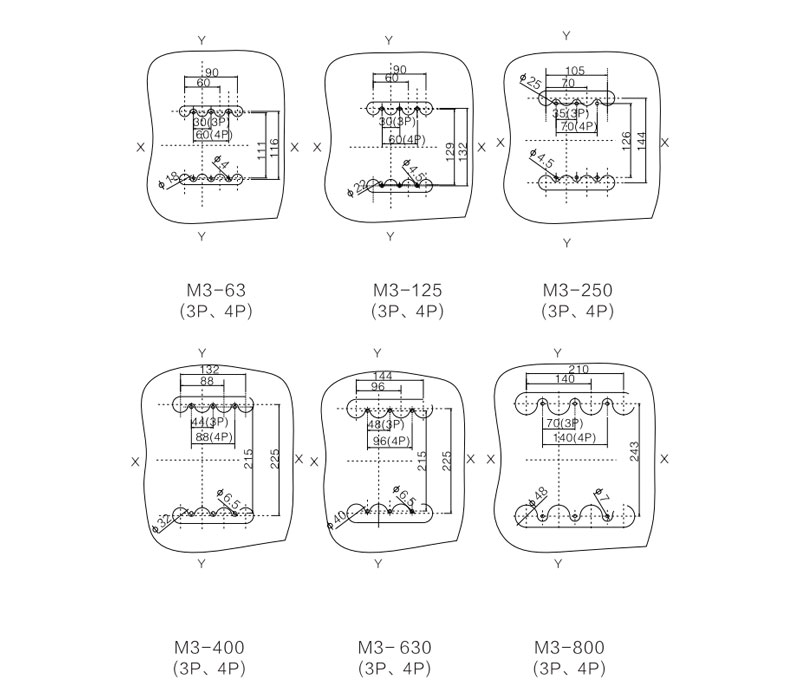

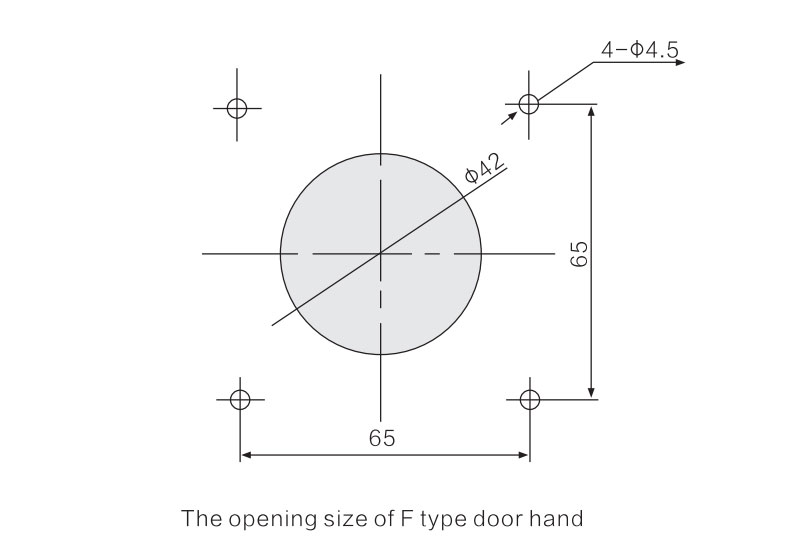

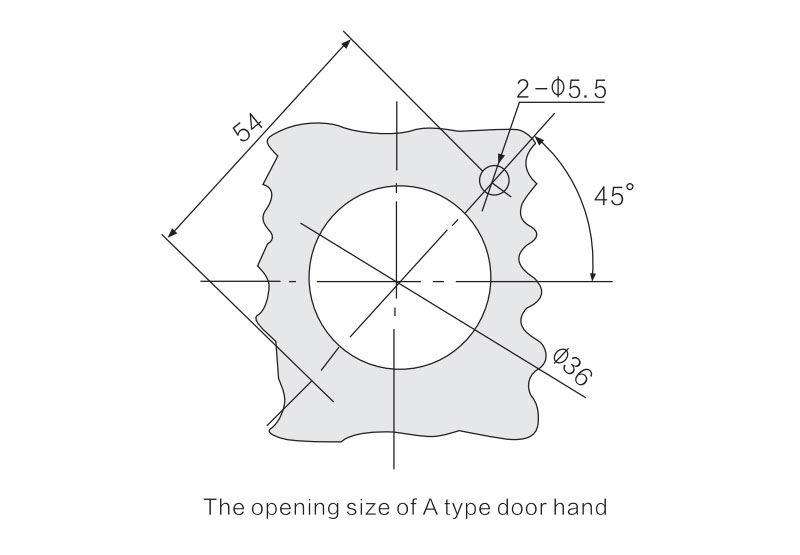

□ The pening of Installation board

□ Front board wiring

X-X、Y-Y is the center of the circuit breaker

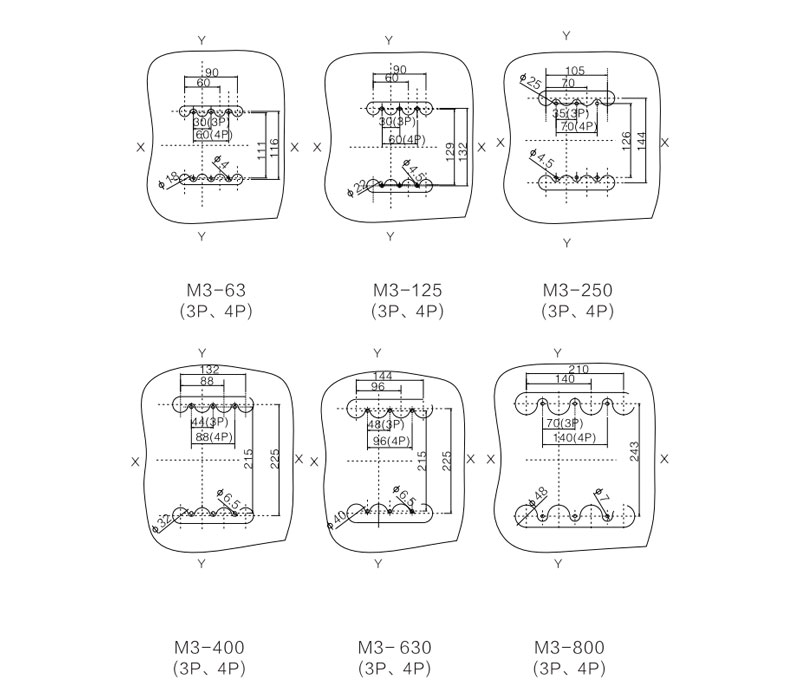

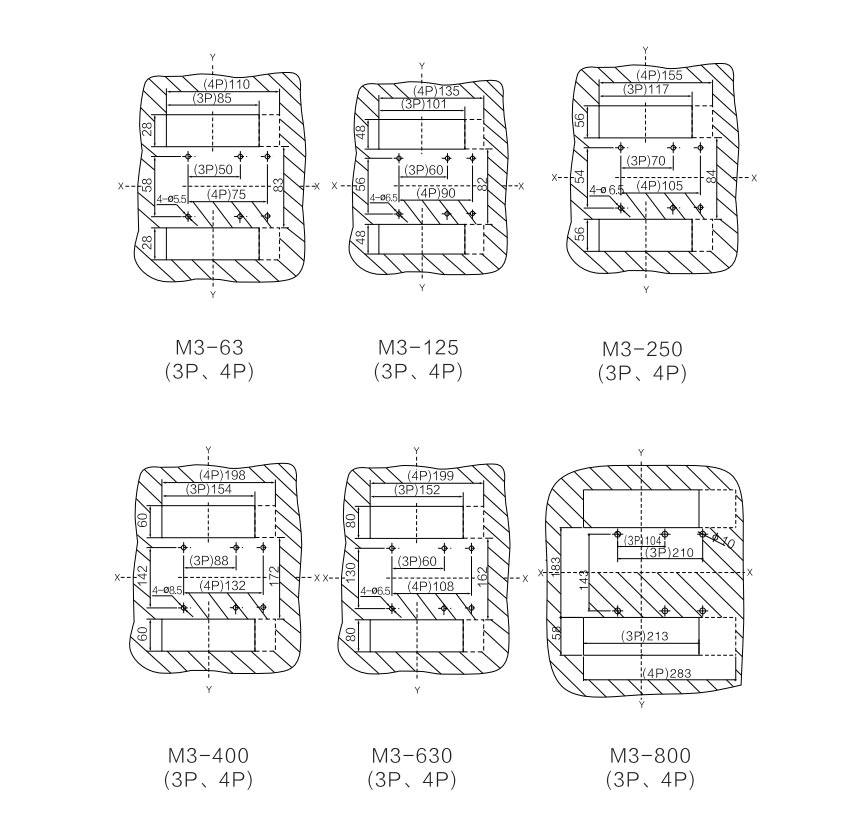

□ Back board wiring

X-X Y-Y is the center of the circuit breaker

□ Plug in type of front board wiring

X-X Y-Y is the center of the circuit breaker

□ Fix the body of the circuit breaker master (back board wiringused) pedestal plug in wiring used on the installation board

□ Connection with the main circuit

a.The cross-sectional area which used for the connect wires mustbe adapted to the rated current table

| Rated Current (A) |

10 |

16/20 |

25 |

32 |

40 |

63 |

80 |

100 |

63/140 |

125 |

180/200

255 |

315 |

400 |

| Cross sectional Area (mm2) |

1.5 |

2.5 |

4 |

6 |

10 |

16 |

25 |

35 |

50 |

70 |

185 |

185 |

240 |

| Rated Current (A) |

Cable |

Copper row |

| Quantity |

Section area (mm2) |

Quantity |

Size (mm) |

| 500 |

2 |

150 |

2 |

30X5 |

| 630 |

2 |

185 |

2 |

40X5 |

| 700/800 |

2 |

240 |

2 |

50X5 |

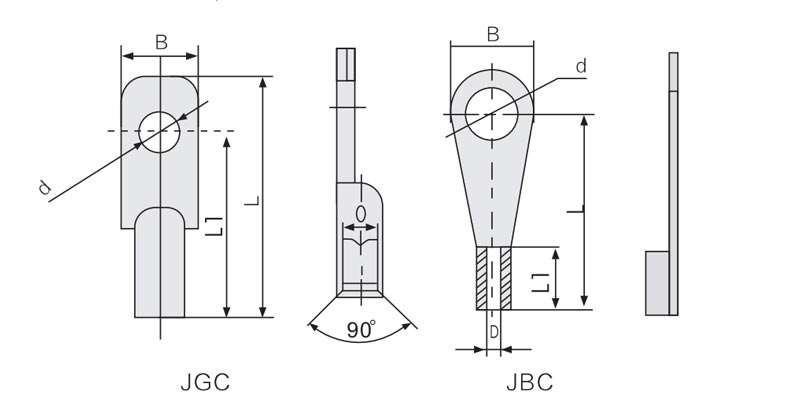

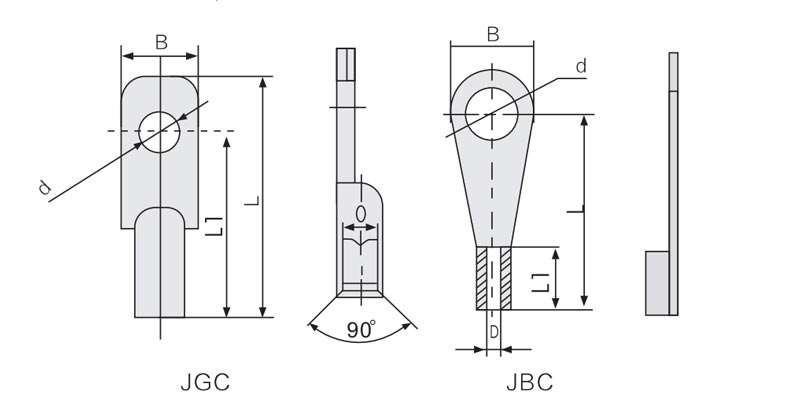

b.Select the connecting terminal

M3 circuit breaker has four types of connecting terminal:

JGC type, JBG type, JBC type or JB type (Offered by users order), follows are the specifications.

| Model |

Rated current (A) |

Corss-sectional Area (mm2) |

Model of terminal |

B |

L |

L1 |

D |

d |

| M3-63 |

10/16/20 |

2.5 |

JBC2.5-8 |

15 |

24.5 |

8.5 |

Φ2.6 |

Φ8.2 |

| 25 |

4 |

JBC4-8 |

13.4 |

20.4 |

9.2 |

Φ2.8 |

Φ8.2 |

| 32 |

6 |

JBC6-8 |

15 |

24.5 |

10 |

Φ3.5 |

Φ8.2 |

| 40/50 |

10 |

JBC10-8 |

15 |

24.5 |

11 |

Φ4.5 |

Φ8.2 |

| 63 |

16 |

JBC16-8 |

12.5 |

41 |

33.5 |

Φ6 |

Φ8.2 |

| M3-125 |

10/16/20 |

2.5 |

JBC2.5-8 |

15 |

24.5 |

8.5 |

Φ2.6 |

Φ8.2 |

| 25 |

4 |

JBC4-8 |

13.4 |

20.4 |

9.2 |

Φ2.8 |

Φ8.2 |

| 32 |

6 |

JBC6-8 |

15 |

24.5 |

10 |

Φ3.5 |

Φ8.2 |

| 40/50 |

10 |

JBC10-8 |

15 |

24.5 |

11 |

Φ4.35 |

Φ8.2 |

| 63 |

16 |

JBC16-8 |

12.5 |

41 |

33.5 |

Φ6 |

Φ8.2 |

| 80 |

25 |

JBC25-8 |

14 |

46 |

38.5 |

Φ7 |

Φ8.2 |

| 100 |

35 |

JBC35-8 |

15.5 |

52 |

44.5 |

Φ8 |

Φ8.2 |

| 125 |

50 |

JBC50-8 |

17 |

54 |

45 |

Φ10 |

Φ8.2 |

| M3-250 |

100 |

35 |

JBC35-8 |

15.5 |

52 |

44.5 |

Φ8 |

Φ8.2 |

| 125/140 |

50 |

JBC50-8 |

17 |

54 |

45 |

Φ10 |

Φ8.2 |

| 160 |

70 |

JBC70-8 |

21.6 |

61 |

52 |

Φ11 |

Φ8.2 |

| 180/200/225 |

95 |

JBC95-8 |

22 |

66 |

57 |

Φ13 |

Φ8.2 |

Note: M3-63, M3-125 the Specifition of current 10A,16A,20A adopt JBC2.5-8; Specification of 32A adopt JBC6-8; Specification of 40A,50A adopt JBC10-8 Wiring terminal.

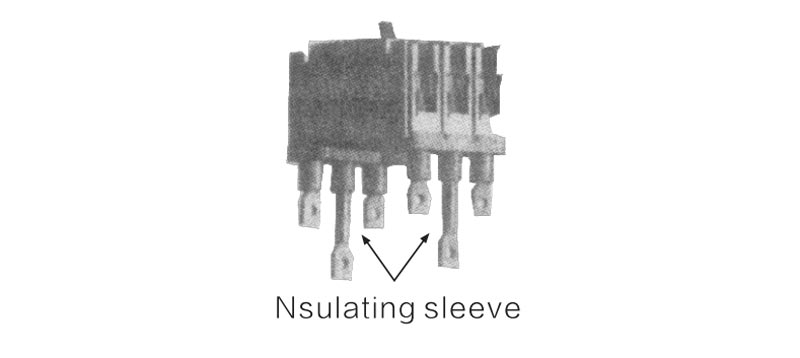

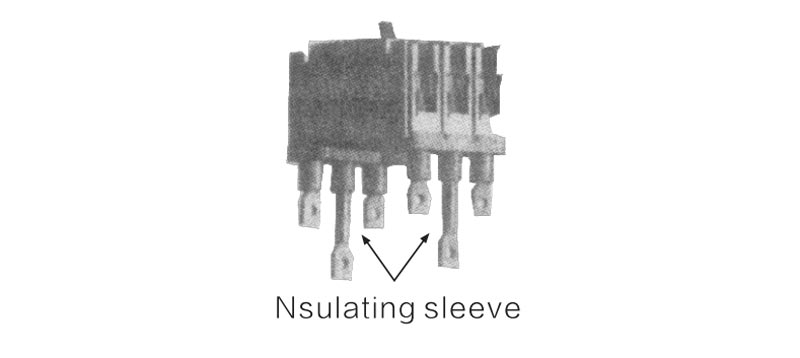

c. The insulating sleeve must be installed on the terminal whenback board wiring

d. Use the bolts (bolts must be set into the flat pad and a springwasher) to connect with a well pressed wire and the conduct of circuit breaker, torque wrench andtighten the bolt, impose the size.

| Model |

Specification of the bolts |

Torque (N.m) |

| M3-63 |

M8 |

6 |

| M3-125 |

M8 |

6 |

| M3-250 |

M8 |

6 |

| M3-400 |

M10 |

10 |

| M3-630 |

M12 |

14 |

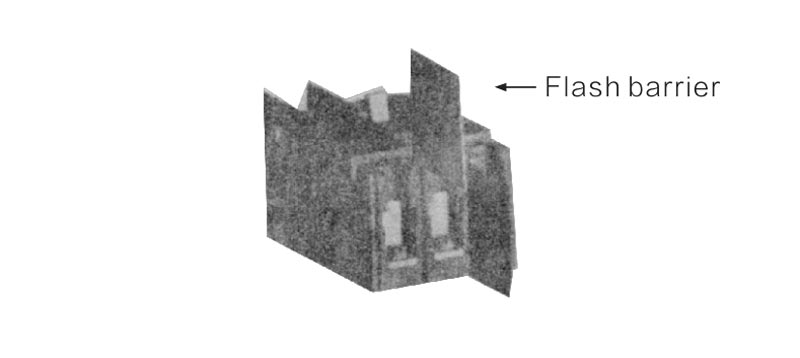

□ Nstall the flash barrier between the circuit breaker.

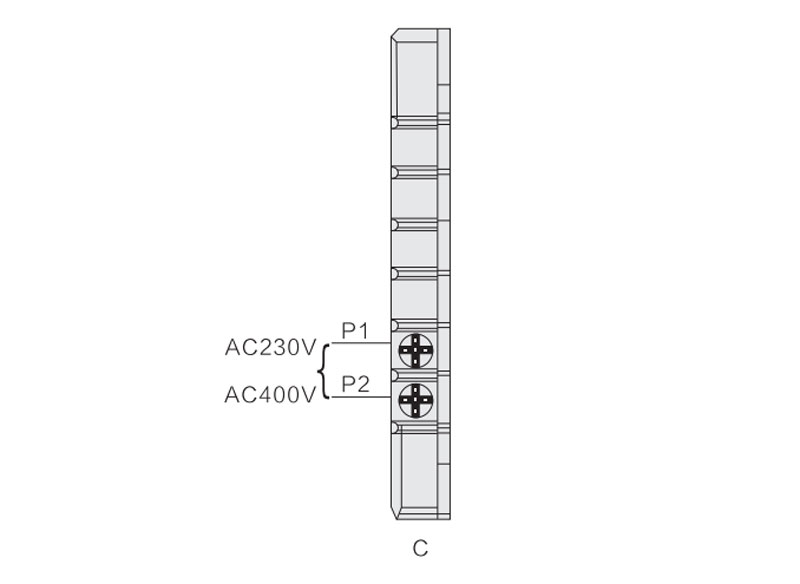

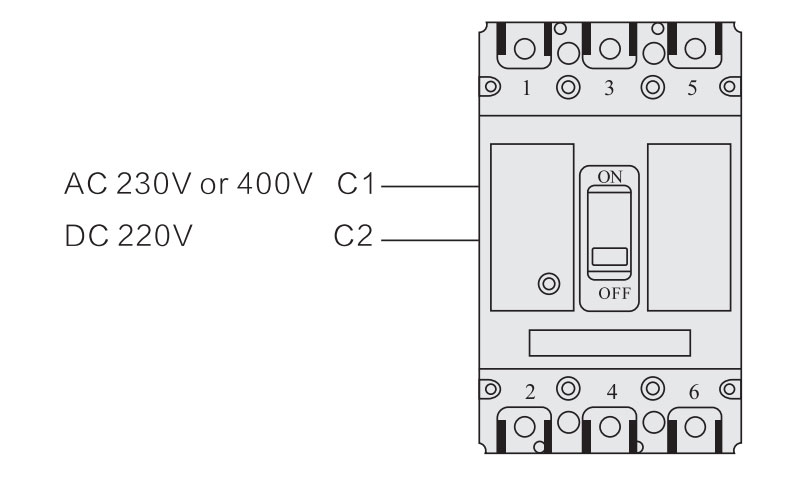

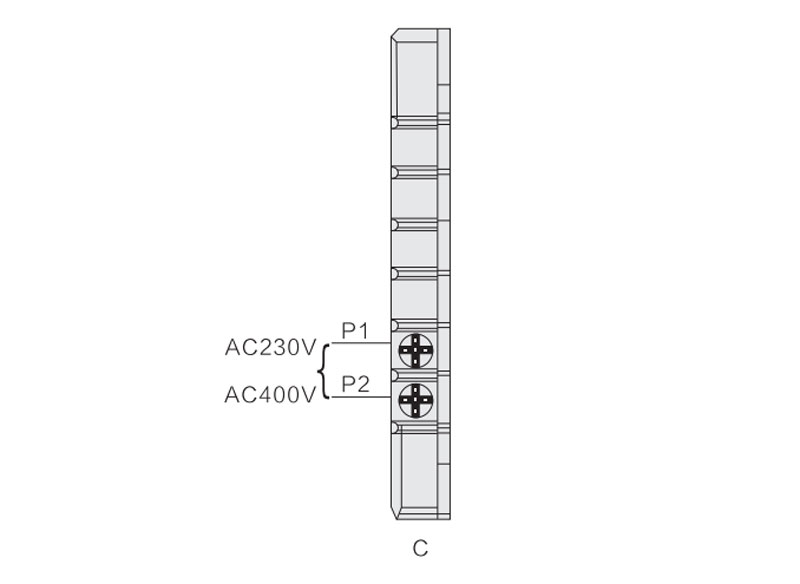

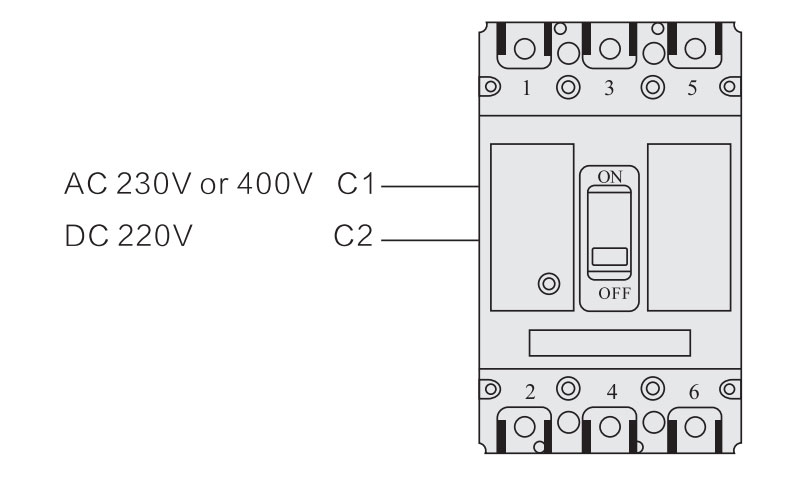

□ The electrical wiring of the internal accessories in the circuit breakera.

a. Under-voltage release according to the number of the connecting terminal in the Plug-in model, then connect it to the power (No need todistinguish between positive and negative when it is DC power)

Note: * When the user adopts the DC24V shunt release, the maximum length of the copper wire (the length of each of the two wires) must meet the requirements of the following table:

| Rated control power supply voltage Us (DC24V) |

Input power |

Copper wire length |

| 1.5mm2 |

2.5mm2 |

| 100%Us |

50w |

150m |

250m |

| 85%Us |

50w |

100m |

160m |

b. Shunt release according to the number of the input wire, then connect it to thepower. No need to distinguish between positive and negative when it is DC power

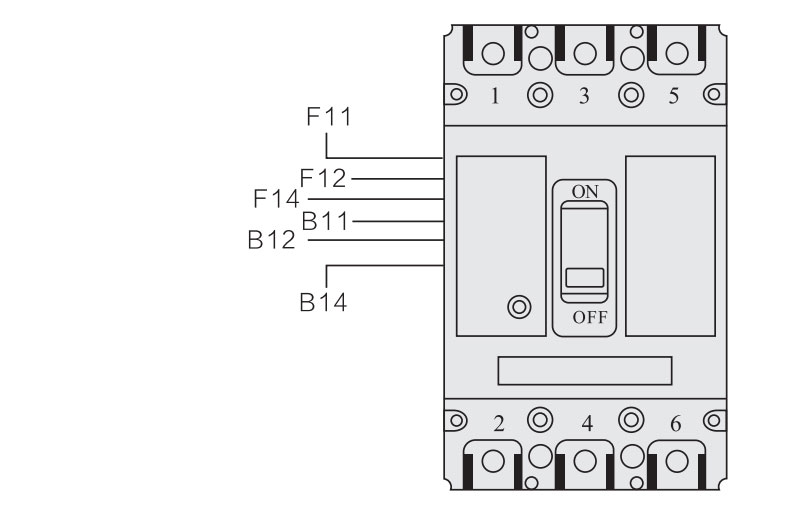

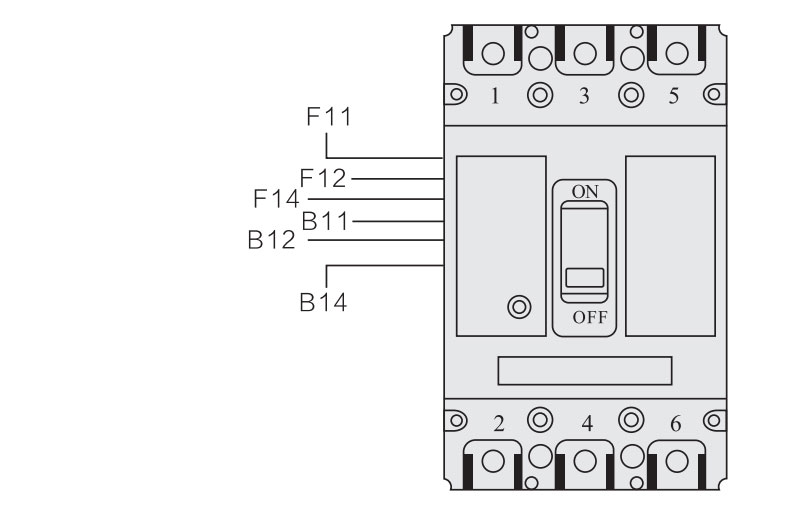

c. Auxiliary contact and Alarm contact according to the number of output wires, connect them to the correspond circuit of the external control.

Note: F11,F12,F14 are the connecting terminal of auxiliary connect;

B11,B12,B14 are the connecting terminal of Alarm contact.

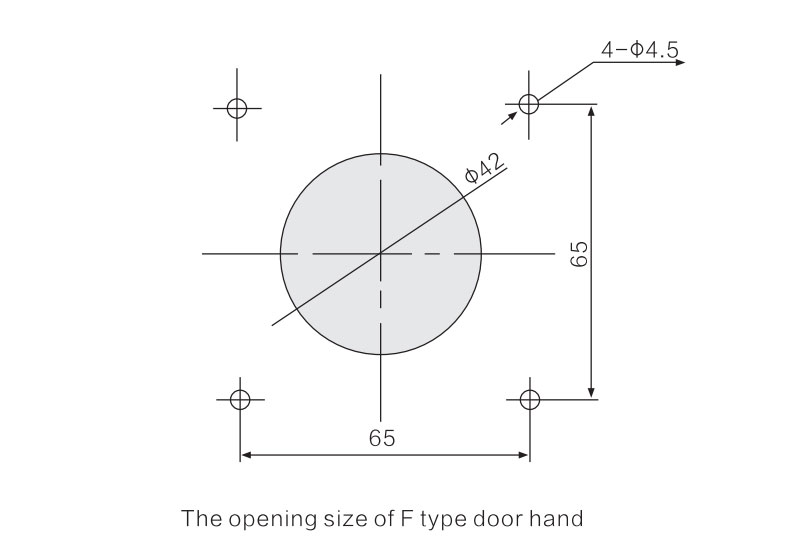

□ lnstall the Turning handle of operating mechanism

a. Before the Installation, there is already a hole for the door of operating handle switch, at the same time (the opening hinge distance from thecenter is not less than 100mm).

b. Fix the circuit breaker which have already install theoperating mechanism in the cover pass.

c. Fix the side-axis joystick in the hole of the operating mechanism.

d. Close the door which have already open the hole, adjust the location of the circuit breaker so that the center of the side-axis and the center of opening hole in the handle are in the same line.

e. Close the switch board doors which have already installed theturning handle, try to operate the handle. The handle should be aglity, when it is setted in the position of horizontal, the circuit breaker should switch on. when it is setted in the position ofvertical, the circuit breaker should be Switch off.

warning

warning