As we are factory, we can guarantee our price is first- hand.

We have professional consultants to give you the most suitable solution.

Delivery time: 1-10 days after received the payment.

We have our own R&D team.

Support OEM/ODM.

MOQ : 1.

As we are factory, we can guarantee our price is first- hand.

We have professional consultants to give you the most suitable solution.

Delivery time: 1-10 days after received the payment.

We have our own R&D team.

Support OEM/ODM.

MOQ : 1.

Dual power automatic switch, The main and backup power sources can be the power grid, the self-starting generator set, the battery group and so on.

Rated current: :16A~630A

Pole: 2P,3P,4P

The components of the product undergo strict agingscreening, and the finished product is powered on for 72 hours. After passing the inspection, It can be packaged. Thereby ensuring the reliability and safety of the product.

This product is mainly used for the primary and secondary loads specified by the state, and is widely used in an important place to supply power continuously. Such as fire protection, post and telecommunications,Communication, hospitals, hotels, urban rail transit, high-rise buildings, industrial assembly lines, television stations, etc.

The main and backup power sources can be the power grid, the self-starting generator set, the battery group and so on.

1. Ambient air temperature: ambient air temperature -5 ° C to +40 ° C, and the 24-hour average temperature value does not exceed+35 ° C. with ambient air temperatures above +40 ° C or below -5 ° C , Users should consult with the manufacturer.

2. Air humidity: when the maximum temperature is +40 degrees, the relative humidity is not more than 50%. Monthly maximum relative humidity 90%,it can tolerate the influence of humid air at sea and allow at lower temperatures. With higher relative humidity, special measures should be taken for the occasional condensation produced by temperature changes.

3. Installation height: the installation site is not more than 2000 meters above sea level. For higher height ,considering the decrease in dielectric strength and cooling effect of air at higher altitudes. Users should consult with the manufacturer.

4. Pollution level: the environmental pollution level of the installation site is level 3.

5. Installation Category: Installation Category is IV.

6. Mounting inclination: The product is fixedly installed in the cabinet with a maximum inclination of ±22.5°.

7. Arcing distance: The arcing distance is 80mm when AC is 400V. The arcing distance can be ignored when using below 125Ampere.

8. Use category: AC-33B.

The product consists of two parts: the switch body and the intelligent ATS controller. The switch body with an electrical and mechanical interlock.

The product used solenoid actuate, double wire loop DC pulse operation, The operation power of the conversion controller adopts the line voltage 220V of main standby power supply.No additional control power.

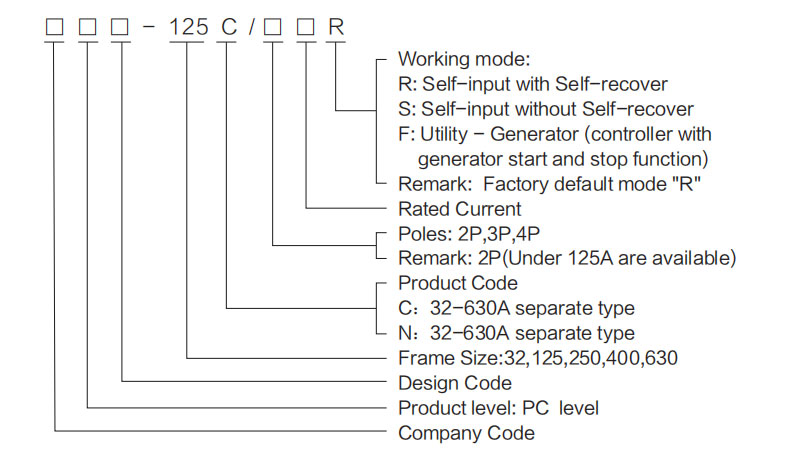

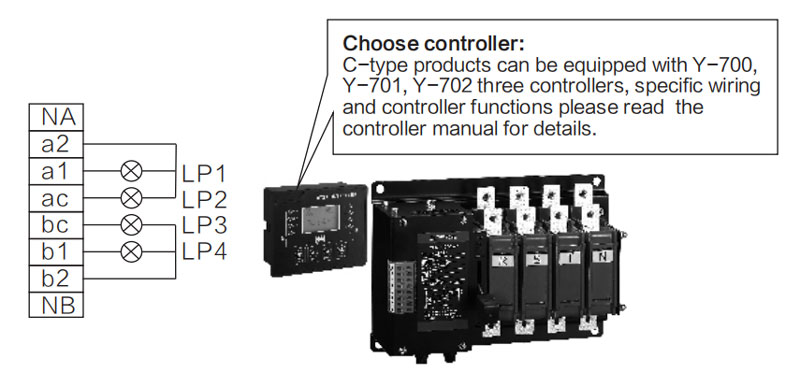

1. Ctype (32A-125A Plug-in type)

Connection terminal schematic diagram

LP2,LP3: Main power and standby power indication

LP1,LP4: Main power and standby power supply indication

NA,NB: Neutral terminal for 3 Pole Power Supply

The split two-position mode is for the convenience of user installation. Our company has changed the connection between the split product controller and the product body into a special connection socket. The user only needs to connect the main circuit and plug in the connection socket to use it, which solves the trouble of user connection difficulty.

2. C (32-125A) Product Installation Dimension

| Type | Dimension | ||||||||||||||

| A | B | C | D | E | F | G | H | HJ | J | K | |||||

| 2P | 3P | 4P | 2P | 3P | 4P | ||||||||||

| 32C | 170 | 197 | 224 | 150 | 177 | 204 | 184 | 167 | 12 | 27 | 3 | 110 | 155 | 5 | 9 |

| 125C | 191 | 228 | 265 | 171 | 208 | 245 | 184 | 167 | 20 | 37 | 3 | 110 | 155 | 8 | 9 |

2. C type(32-125A) Technical Data

| Rated working current(A) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | |

| Rated control voltage (V) | AC220 | ||||||||||

| Rated control current (A) | 3.5 | ||||||||||

| Rated short-time withstand current (KA) | 10 | ||||||||||

| Service life | Mechanical life | 20000 | |||||||||

| Electrical life | 6000 | ||||||||||

| Operating cycle (1minute /times) | 10 | ||||||||||

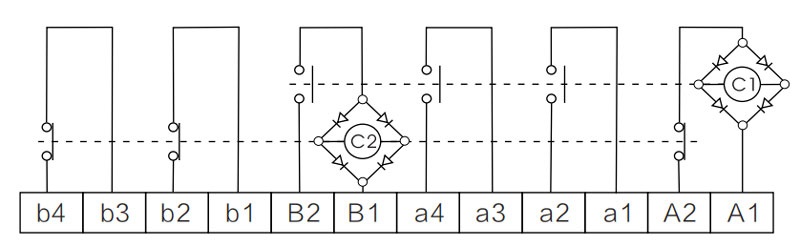

1. C type product electrical schematic diagram

Note: In the absence of a dedicated ATS controller, the two power sources in the controller circuit can not be simultaneously energized.

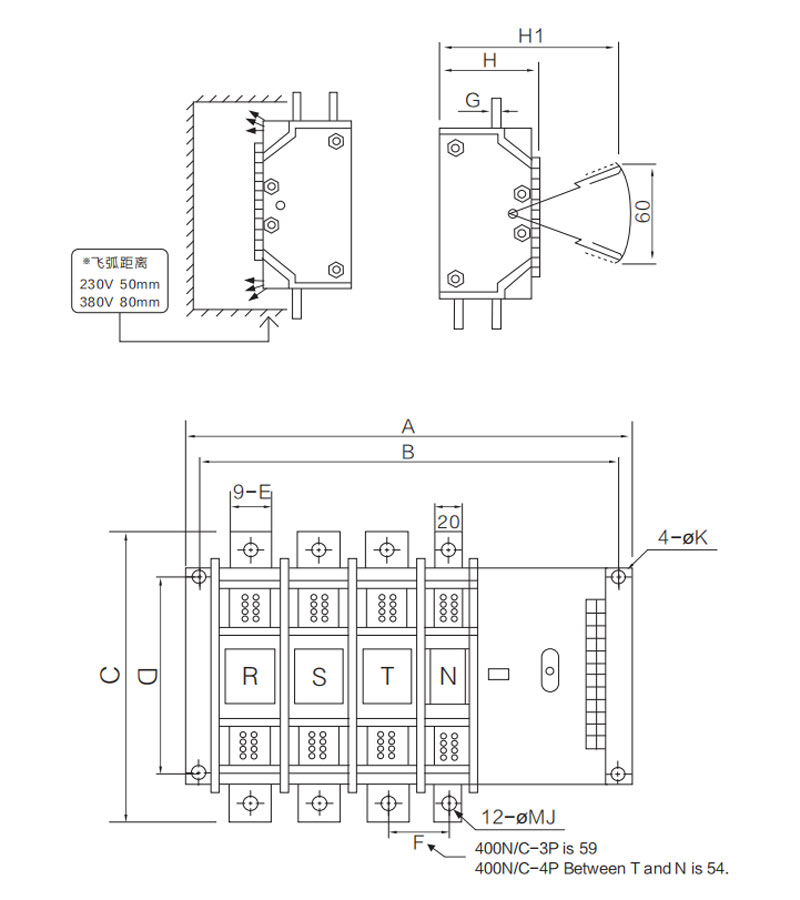

2. C type (160A-630A) Product Installation Dimension

| Type | Dimension | ||||||||||||

| A | B | C | D | E | F | G | H | H1 | J | K | |||

| 3P | 4P | 3P | 4P | ||||||||||

| 250A | 322 | 372 | 302 | 352 | 294 | 200 | 20 | 49 | 5 | 146 | 295 | 8 | 10 |

| 400A | 352 | 402 | 332 | 382 | 294 | 200 | 30 | 59 | 6 | 146 | 295 | 10 | 10 |

| 630A | 352 | 412 | 332 | 392 | 294 | 200 | 35 | 59 | 6 | 146 | 295 | 12 | 10 |

3. C/N type(160A-630A) Technical Data

| Rated working current(A) | 160A | 180A | 200A | 225A | 250A | 315A | 350A | 400A | 500A | 630A | |

| Rated control voltage (V) | AC220 | ||||||||||

| Rated control current (A) | 7 | ||||||||||

| Rated short-time withstand current (KA) | 10 | ||||||||||

| Service life | Mechanical life | 17000 | |||||||||

| Electrical life | 6000 | ||||||||||

| Operating cycle (1minute /times) | 15 | ||||||||||

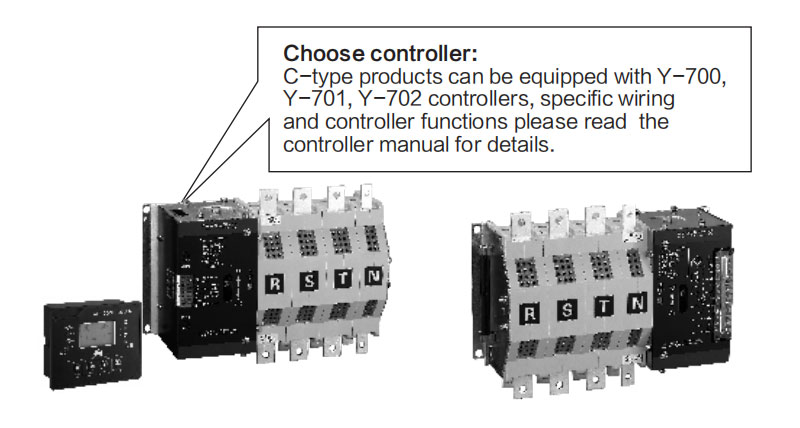

According to the market demand, our company has developed a variety of product controllers. N/C series products can be equipped with Y-700, Y-701, Y-702 controllers. For the functions and wiring modes of the controllers, see the controller instructions.

| Model | Type | |||||||

| YES1-32C | YES1-125C | YES1-400C | ||||||

| Rated Current(Amp) | 16A~32A | 40A~125A | 160A~630A | |||||

| Rated Control Current(Amp) | 5A | 7A | ||||||

| Rated Short Circuit Current(Amp) | 10A | |||||||

| The Rated Impulse with Stand Voltage(KV) | 8 | |||||||

| Usingzation Category | AC - 33B | |||||||

| Mechanical Life | 20000 | 17000 | ||||||

| Electric Life | 6000 | |||||||

| Pole | 2P | 3P | 4P | 2P | 3P | 4P | 3P | 4P |

| Weight(kg) | 3.2 | 3.7 | 4.2 | 4 | 4.5 | 5.5 | 18.5 | 20.5 |

| Operating Cycle(S/Time) | 10 | |||||||

The work in the installation and commissioning of the product shall be carried out by professionals or those who have knowledge of the switchgear. Corresponding protection and precautions must be taken into account during operation. The main circuit of the switch must be wired in such a way that the leads are not subjected to any pressure or force.Before installation and commissioning, checking that the switch is not damaged or any other hazardous environmental impact, and it also should check whether the thread is loose due to transportation. Remove dirt, especially the dirt on the surface of the insulationparts. When connecting the primary circuit, it should be noted that the phase sequence of the normal power and standby power must be the same. When connecting the secondarycircuit control loop, it should be strictly in accordance with the wiring diagram in Instruction manual while paying attention to the control power supply voltage level, the switch must be installed with good grounding.

Considering personal safety and switching speed, the debugging handle is only used for debugging. Users is not allowed use the debugging handle with load operation. And it is not allowed use when the arc extinguishing device is not installed. When debugging, the switch is operated with the debugging handle .To observe the close of the main contact and Running conditions.All are no abnormal situation, then the ATS switch can be work.

1. After debugging Controller and part of mechanical ,the controller and electrical part can be adjustedof the power-on debugging, the load is prohibited during the debugging process.

2. Put in the normal power into the products, the normal power indicator is light up, and then put in the standby power ,the standby power indicator is light up. and press the“Manual/Auto” button is placed in the manual position,Then press the "main power manual" button,The ATS will transfer to Main power quickly, The normal power indicator and external connecting indicator lamp is light up.Press the "standby power Manual", The ATS will transfer to Standby power quickly, The standby power indicator and external connecting indicator lamp is light up.

3. The "Manual/Auto" buttonis placed in the automatic position, delay time of normal power and standby power are adjusted to the appropriate value. The normal power supply is disconnected first, and the indicator of normal power Switch on is flashed on. When reached the setting of delay time value, The ATS will quickly switch to standby power supply automatically.The standby power indicator and external connecting indicator lamp is light up.

When the main power is return,the ATS will switch to Normal power supply, the indicator of standby power switch on is flashes, When reached the setting of delay time value, the ATS will quickly transfer to the normal power supply, The normal power indicator and external connecting indicator lamp is light up.

1. In normal using, the controller should be placed in the automatic position ,The ATS is in the automatic control mode, The controller monitors both the main power and the backup power simultaneously and displays status. When the main power source has failure, such as power cut, under-voltage, over-voltage, or phase loss, The ATS will transfer to Standby power automatically. The power delay time is in 0~30 second. When the main power return, the ATS will transfer from Standby

power to Main power automatically. The controller is provided with a light-emitting diode to indicate condition of switch and power supply.

2. If you do not want the ATS switch automatically, or When other manual operations are required, you should set the controller in Manual position. When it is in Manual mode, the ATS is not transfer automatically.

3. When the ATS is in automatic mode,if the main power supply and the standby power supply are in normal condition. The ATS will give priority to connecting the main power supply to the load.

When the product does not work or work abnormally, first check the following points:

a. Is the switch body and the controller connected good or not? Is the connection correct?

b. Is the power turned on?

c. Is the controller in manual mode?

d. Is the voltage normal?

e. Is the switch body and the controller of main and standby power inputs opposite?

f. Is the fuse intact?

g. Is the debug line too long when debugging? Is the wire diameter too thin?

h. Whether to distinguish between neutral line N , phase line and PE ground line during debugging?

This series of dual power automatic switch is a high-tech product developed by our company using the latest technology. It is high reliability and guarantee,In the operation, abnormal phenomena may occur. If the problem cannot be solved according to the above points, please contact our after-sales service department.

From June 6 to 9, 2023, the 48th Moscow International Power Electronics Exhibition (ELEKTRO) Pavilion opened its doors to the public, and One Two Thre...

Exhibition previewTime flies, after three years of anti-epidemic efforts, remarkable results have been achieved. This year, 2023, trade flows will vas...

First of all, Schneider's low-voltage products include circuit breakers, switches, contactors, relays, etc., which are basically world famous brands.S...

In the design of a dual power transfer switch, the most important is the current control module (TCM), because the current is not strong enough to mee...

GET A QUOTE