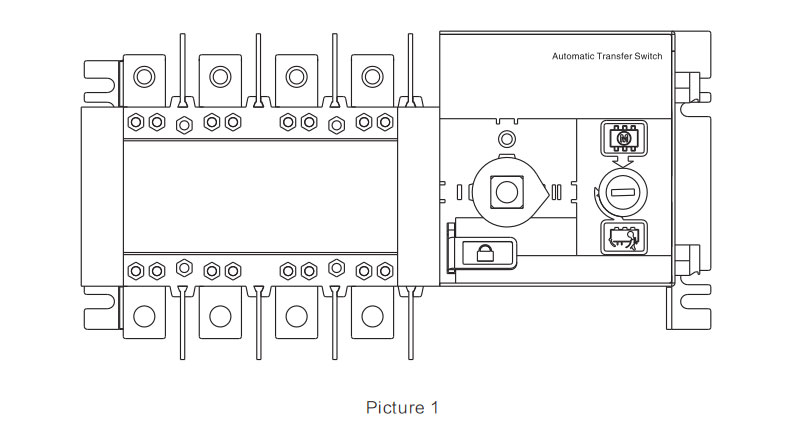

YES1 series ATSE is made up of switch body and transfer controller. The switch is driven by electromagnetic coil, so the transier speed is very fast. The power source of controller takes main power or emergency power AC220V as working voltage.

YES1 series ATSE is made up of switch body and transfer controller. The switch is driven by electromagnetic coil, so the transier speed is very fast. The power source of controller takes main power or emergency power AC220V as working voltage.

Rated current: 16A~3200A

Pole: 4P

Before you operate this Automatic transfer switch (hereinafter ATS),please read and understand these instructions carefully.

▲Before you install or operate the ATS,please read and understand these instructions carefully.Only the professional ATS personnel can carry out this installation,adjustment, repair and maintenance.

▲Many parts of the ATS, including printed circuit boards, when it work on-line voltage, cannot touch these parts. Use insulated tools only.

▲Do not touch the components which not protected.

▲Before maintenance the line of ATS, we should take the following preventive measures:

- Disconnect all power.

- Put a "prohibited closing" signs before the locate of the switch

- Switch to "0" position and then hang padlock.

Inconsistent with the line voltage:

Before Power and configuration for the ATS , we must ensure the line voltage is in the scope of the power supply voltage in the name plate of the ATS If the line voltage and power supply voltage range is different ,it will damage the ATS.Using it not according to the instructions it will damage the equipment.

■ ATS delivery

Check and make sure the product is the ordering products.

■ Check the voltage

Check and make sure the voltage and the working voltage of the ATS.

Whether it is in the scope of the voltage.

■ Install the ATS

Install the ATS according this manual instruction.

Install all the external accessories.

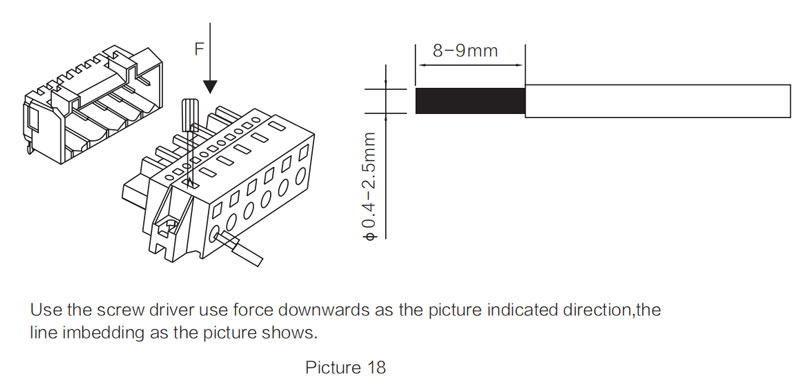

■ Wiring the ATS

Connect the bus bar of the switch which coincided with the rated current.

Connect the control wire and outside indication well according to the manual instruction.

| Frame class | 100 | 250 | 1600 | 3200 | ||||||||||||||||||

| Agreed heating current Ith(A) | 63 | 100 | 160~3200 | |||||||||||||||||||

| Rated current In(A) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 250 | 400 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3200 | |

| Rated insulation voltage(Ui) | 690V | 800V | ||||||||||||||||||||

| Rated concussion withstand voltage(Uimp) | 8KV | |||||||||||||||||||||

| Rated working voltage(Ue) | AC400V | |||||||||||||||||||||

| Rated working current (le) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 250 | 400 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3200 | |

| Using category | AC-33B | AC-33iB | ||||||||||||||||||||

| Rated short-circuit connection capacity | 8KA | 26KA | 67KA | |||||||||||||||||||

| Rated short-time withstand current(Icw) | 5kA/30ms | 12.6kA/60ms | 32kA/60ms | |||||||||||||||||||

| Transfer time Ⅰ-Ⅱ or Ⅰ-Ⅱ | 2.5s | 0.6s | 1.2s | 1.8s | 2.4s | |||||||||||||||||

| Control voltage | DC24V, 48V, 110V, AC220V | |||||||||||||||||||||

| Rated frequency | Start | 20W | 325W | 355W | 400W | 440W | 600W | |||||||||||||||

| Norma | 62W | 74W | 90W | 98W | 120W | |||||||||||||||||

| Weight(kg) 4Pole | 3.4 | 6 | 7.6 | 15.8 | 16.8 | 36 | 36 | 37 | 38.6 | 55 | 61 | 67 | ||||||||||

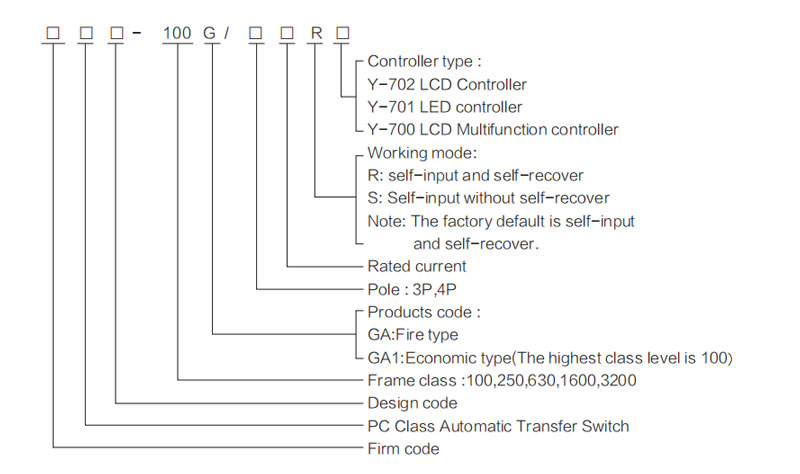

① Electric key lock:Control the inside controlling line power supply of the switch,when the Electric lock open,the switch could be operated automatically and remotely, when the electric lock closed,the switch could be operated by handle only.

② Operating handle: When operate the switch by the operating handle, the electric lock must be closed.

③ Mechanic padlock:When inspection,firstly turn the switch to the"0" position by operationhandle,then pull the padlock mechanism and close the padlock,then the inspection can be arranged:(Pull the mechanism padlock will cut off the inside controlling power supply of the switch.The switch couldn't be inelectric position and also couldn't be manual operation.

④ Position indication:It means the position of the switch working estate (Ⅰ,0,Ⅱ)

⑤ Controlling voltage: AC220V

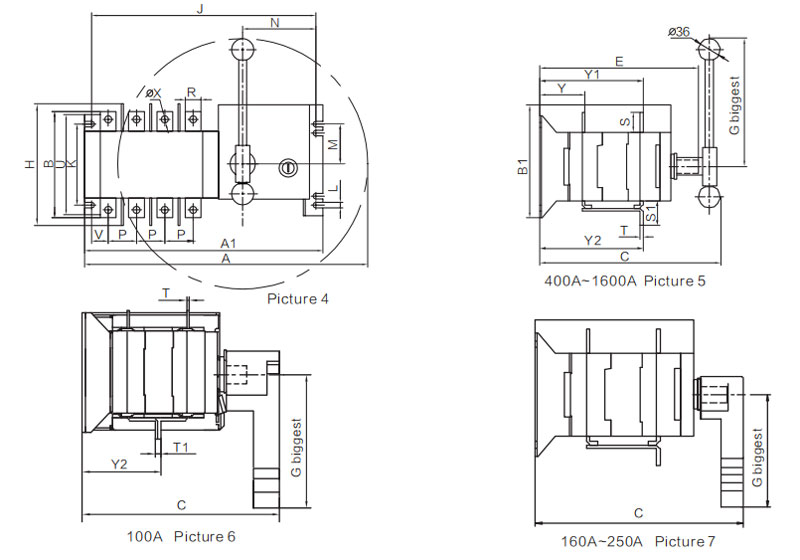

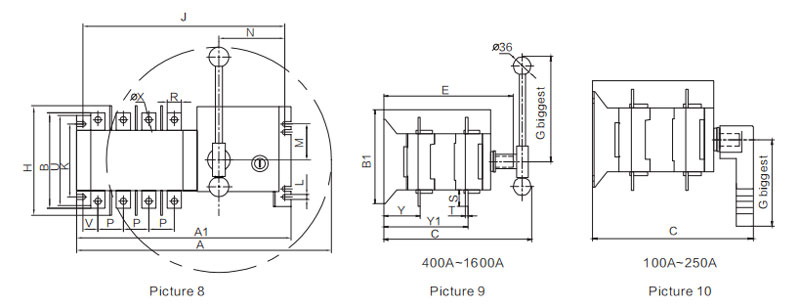

16A~1600A installation diagram ( 2 input 1 output )

16A~1600A installation dimensions( 2 input 1 output )

| Specification | Total dimension | Switch installation | Connection terminal | ||||||||||||||||||||||

| A | A1 | B | B1 | C | E | G | H | J | K | L | M | N | P | R | S | S1 | T | T1 | U | V | ΦX | Y | Y1 | Y2 | |

| 16~100A | 270 | 245 | 110 | 103 | 170 | 142 | 115 | 146 | 226 | 84 | 7 | 44 | 81 | 30 | 14 | 18 | 23 | 2.5 | 5 | 103 | 12 | 6 | 40.5 | 92 | 67.5 |

| 125~160A | 348 | 305 | 147 | 142 | 224 | 190 | 144 | 185 | 284 | 102 | 7 | 49 | 91 | 36 | 20 | 25 | 37 | 3.5 | / | 127.5 | 19 | 9 | 56 | 127.5 | 127.5 |

| 250A | 411 | 368 | 170 | 142 | 224 | 190 | 144 | 200 | 347 | 102 | 7 | 49 | 91 | 50 | 25 | 29 | 40 | 3.5 | / | 141.5 | 28 | 11 | 56 | 130 | 130 |

| 400A/3P | 525 | 374 | 234 | 222 | 305 | 268 | 250 | 290 | 354 | 179 | 9 | 96 | 91 | 65 | 32 | 37 | 52 | 5 | / | 222 | 38 | 11 | 83 | 193 | 193 |

| 400A/4P | 585 | 435 | 234 | 222 | 305 | 268 | 250 | 290 | 415 | 179 | 9 | 96 | 91 | 65 | 32 | 37 | 52 | 5 | / | 222 | 38 | 11 | 83 | 193 | 193 |

| 630A/3P | 525 | 374 | 250 | 222 | 305 | 268 | 250 | 290 | 354 | 179 | 9 | 96 | 91 | 65 | 40 | 45 | 61 | 6 | / | 222 | 38 | 12 | 83.5 | 193.5 | 196 |

| 630A/4P | 585 | 435 | 250 | 222 | 305 | 268 | 250 | 290 | 415 | 179 | 9 | 96 | 91 | 65 | 40 | 45 | 61 | 6 | / | 222 | 38 | 12 | 83.5 | 193.5 | 196 |

| 800~1000A/3P | 785 | 520 | 328 | 250 | 390 | 326 | 360 | / | 496 | 220 | 11 | 115 | 84 | 120 | 60 | 64 | 88 | 8 | / | 250 | 56.5 | 13 | 109 | 254 | 254 |

| 800~1000A/4P | 1080 | 635 | 328 | 250 | 390 | 326 | 540 | / | 610 | 220 | 11 | 115 | 84 | 120 | 60 | 64 | 88 | 8 | / | 250 | 60.5 | 13 | 109 | 254 | 254 |

| 1250A/3P | 785 | 520 | 336 | 250 | 390 | 326 | 360 | / | 496 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 100 | 8 | / | 250 | 56.5 | 13 | 109 | 254 | 254 |

| 1250A/4P | 1080 | 635 | 336 | 250 | 390 | 326 | 540 | / | 610 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 100 | 8 | / | 250 | 60.5 | 13 | 109 | 254 | 254 |

| 1600A/3P | 785 | 520 | 336 | 250 | 390 | 326 | 360 | / | 496 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 108 | 10 | / | 250 | 56.5 | 13 | 110 | 255 | 255 |

| 1600A/4P | 1080 | 635 | 336 | 250 | 390 | 326 | 540 | / | 610 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 108 | 10 | / | 250 | 60.5 | 13 | 110 | 255 | 255 |

16A~1600A installation diagram ( 2 input 2 output )

1000A~1600A installation diagram

16A~1600A installation dimensions ( 2 input 2 output )

| Specification | Total dimension | Switch installation | Connection terminal | |||||||||||||||||||

| A | A1 | B | B1 | C | E | G | H | J | K | L | M | N | P | R | S | T | U | V | ΦX | Y | Y1 | |

| 16~100A | 270 | 245 | 106 | 103 | 170 | 142 | 115 | 146 | 226 | 84 | 7 | 44 | 81 | 30 | 14 | 18 | 2.5 | 103 | 12 | 6 | 40.5 | 92 |

| 125~160A | 348 | 305 | 135 | 142 | 224 | 190 | 144 | 185 | 284 | 102 | 7 | 49 | 91 | 36 | 20 | 25 | 3.5 | 127.5 | 19 | 9 | 56 | 127.5 |

| 250A | 411 | 368 | 159 | 142 | 224 | 190 | 144 | 200 | 347 | 102 | 7 | 49 | 91 | 50 | 25 | 29 | 3.5 | 141.5 | 28 | 11 | 56 | 130 |

| 400A/3P | 525 | 374 | 234 | 222 | 305 | 268 | 250 | 290 | 354 | 179 | 9 | 96 | 91 | 65 | 32 | 37 | 5 | 222 | 38 | 11 | 83 | 193 |

| 400A/4P | 585 | 434 | 234 | 222 | 305 | 268 | 250 | 290 | 414 | 179 | 9 | 96 | 91 | 65 | 32 | 37 | 5 | 222 | 38 | 11 | 83 | 193 |

| 630A/3P | 525 | 374 | 250 | 222 | 305 | 268 | 250 | 290 | 354 | 179 | 9 | 96 | 91 | 65 | 40 | 45 | 6 | 222 | 38 | 12 | 83.5 | 193.5 |

| 630A/4P | 585 | 434 | 250 | 222 | 305 | 268 | 250 | 290 | 414 | 179 | 9 | 96 | 91 | 65 | 40 | 45 | 6 | 222 | 38 | 12 | 83.5 | 193.5 |

| 800~1000A/3P | 785 | 520 | 328 | 250 | 390 | 326 | 360 | / | 496 | 220 | 11 | 115 | 84 | 120 | 60 | 64 | 8 | 250 | 56.5 | 13 | 109 | 254 |

| 800~1000A/4P | 1080 | 635 | 328 | 250 | 390 | 326 | 540 | / | 610 | 220 | 11 | 115 | 84 | 120 | 60 | 64 | 8 | 250 | 60.5 | 13 | 109 | 254 |

| 1250A/3P | 785 | 520 | 336 | 250 | 390 | 326 | 360 | / | 496 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 8 | 250 | 56.5 | 13 | 109 | 254 |

| 1250A/4P | 1080 | 635 | 336 | 250 | 390 | 326 | 540 | / | 610 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 8 | 250 | 60.5 | 13 | 109 | 254 |

| 1600A/3P | 785 | 520 | 336 | 250 | 390 | 326 | 360 | / | 496 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 10 | 250 | 56.5 | 13 | 110 | 255 |

| 1600A/4P | 1080 | 635 | 336 | 250 | 390 | 326 | 540 | / | 610 | 220 | 11 | 115 | 84 | 120 | 80 | 68 | 10 | 250 | 60.5 | 13 | 110 | 255 |

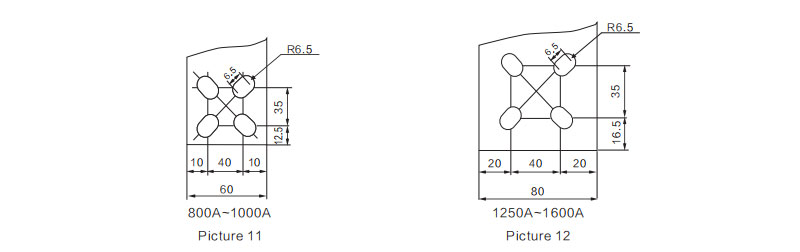

2000A~3200A installing dimensions

2000A~3200A installing dimensions

| Specification | A | A1 | B | G | J | R | S | T | V | Y1 | Y2 |

| 2000A/3P | 785 | 537 | 423 | 360 | 496 | 80 | 81 | 10 | 56 | 113 | 121 |

| 2000A/4P | 1080 | 651 | 423 | 540 | 610 | 80 | 81 | 10 | 72 | 113 | 121 |

| 2500A/3P | 785 | 537 | 433 | 360 | 496 | 80 | 81 | 15 | 56 | 118 | 116 |

| 2500A/4P | 1080 | 651 | 433 | 540 | 610 | 80 | 81 | 15 | 72 | 118 | 116 |

| 3200A/3P | 785 | 537 | 443 | 360 | 496 | 80 | 81 | 20 | 56 | 123 | 111 |

| 3200A/4P | 1080 | 651 | 443 | 540 | 610 | 80 | 81 | 20 | 72 | 123 | 111 |

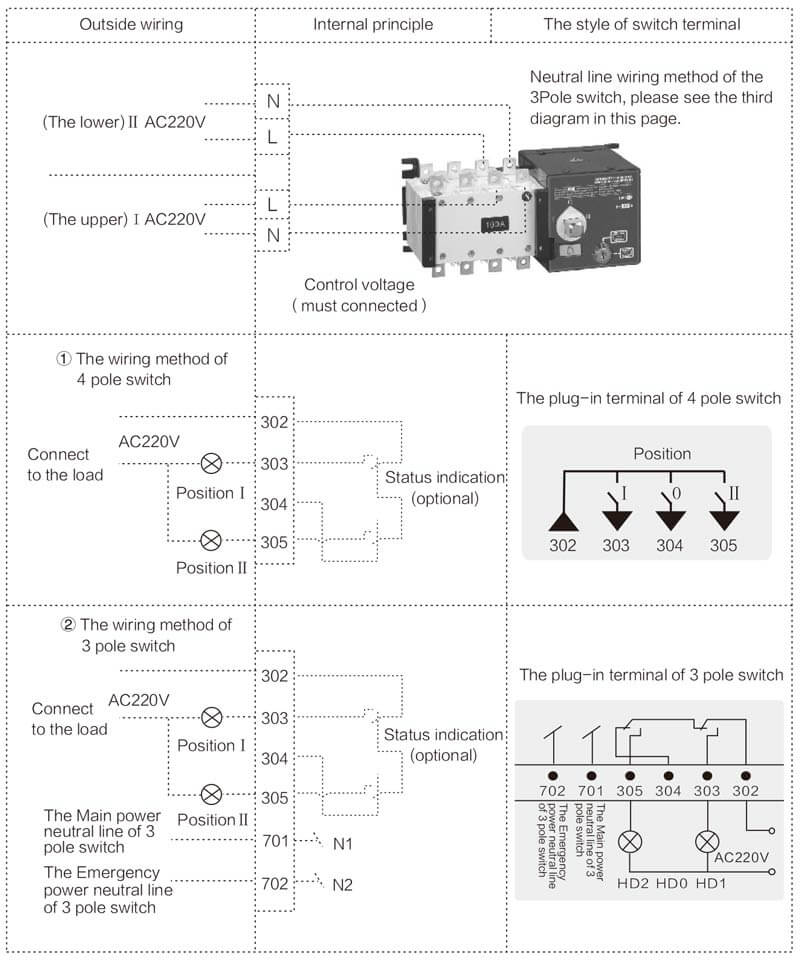

1. GA1 type Economic ATS manual instruction(Fit for rated current:16A-100A)

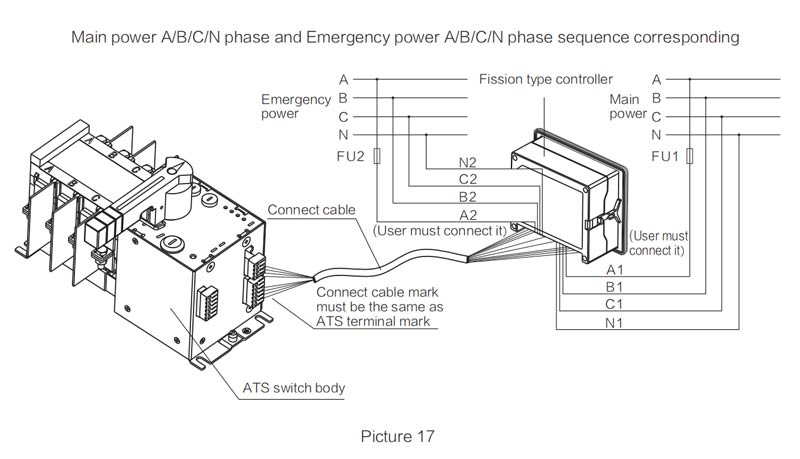

Note: Please pay attention to Main power and Emergency power phase sequence corresponding relation when you are wiring the switch.

2. GA type fire type ATS manual instruction(Fit for rated current:16A-3200A)

Note: Please pay attention to Main power and Emergency power phase sequence corresponding relations when you are wiring the switch.

Note: Controller manual instruction please to see the Y-701/702 user manual

| Model | Type | ||||

| YES1-100GA | YES1-250GA | YES1-630GA | YES1-1600GA | YES1-3200GA | |

| Rated Current(Amp) | 16A~100A | 125A~250A | 315A~630A | 800A~1600A | 2000A~3200A |

| Rated Insulation Voltage | 690V | 800V | |||

| Rated Impulse with Stand Voltage(KV) | 8 KV | ||||

| Rated Working Voltage | AC400V | ||||

| Usingzation Category | AC - 33B | AV - 33iB | |||

| Rated Short-Time with Stand Current | 5KA/30ms | 10KA/60ms | 12.6KA/60ms | 21KA/60ms | |

| Transfer Time | 2.5s | 0.6s | 1.2s~2.4s | ||

| Control Power Voltage | DC24V、48V、110V AC220V | ||||

| Vote Number | Double Throw | ||||

| Wiring Manner | Panel Mounting | ||||

| Pole | 4P | ||||

| Weight(kg) | 3.4 | 7.6 | 16.8 | 38.6 | 67 |

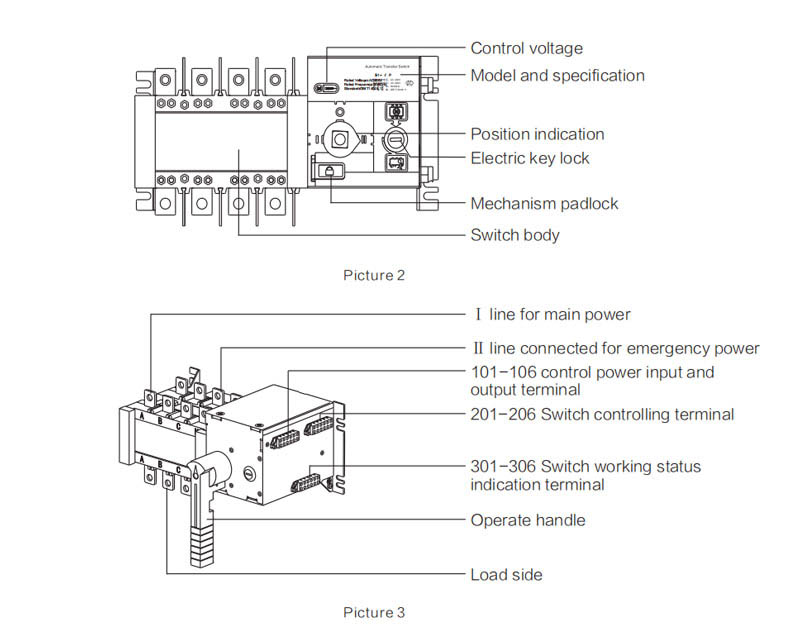

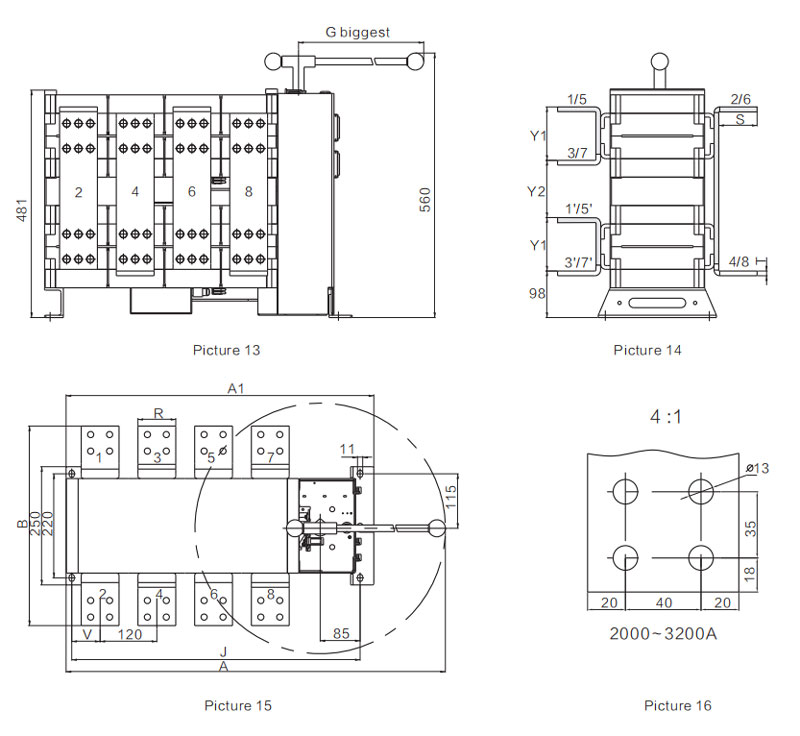

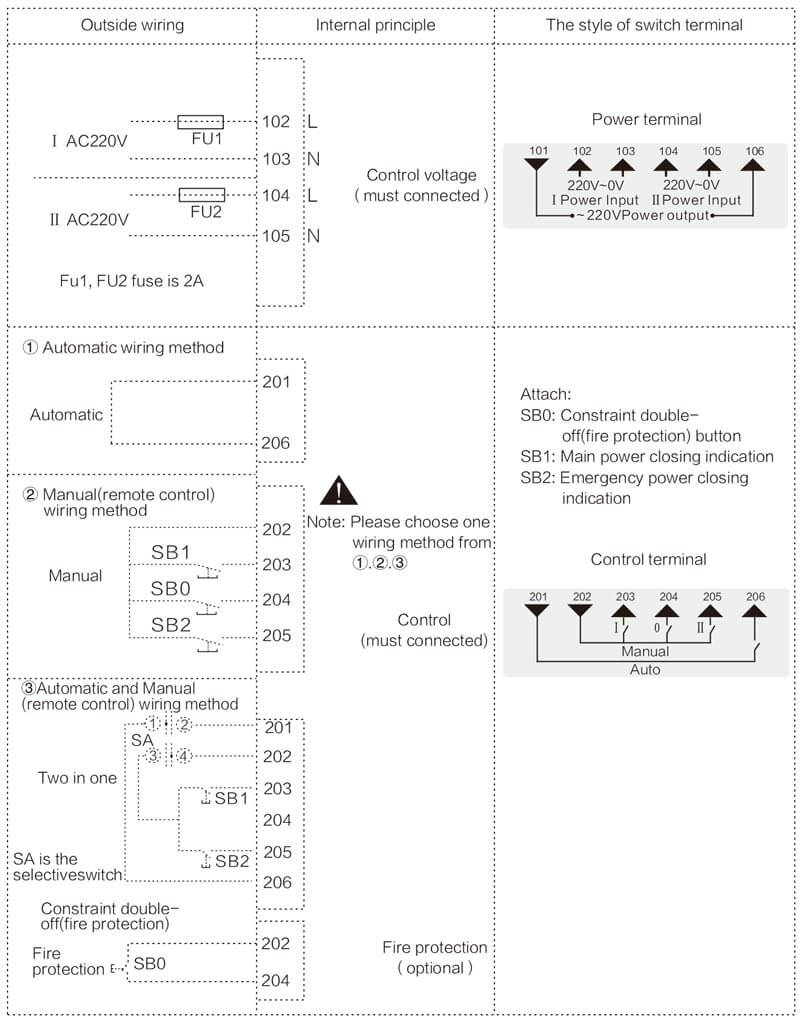

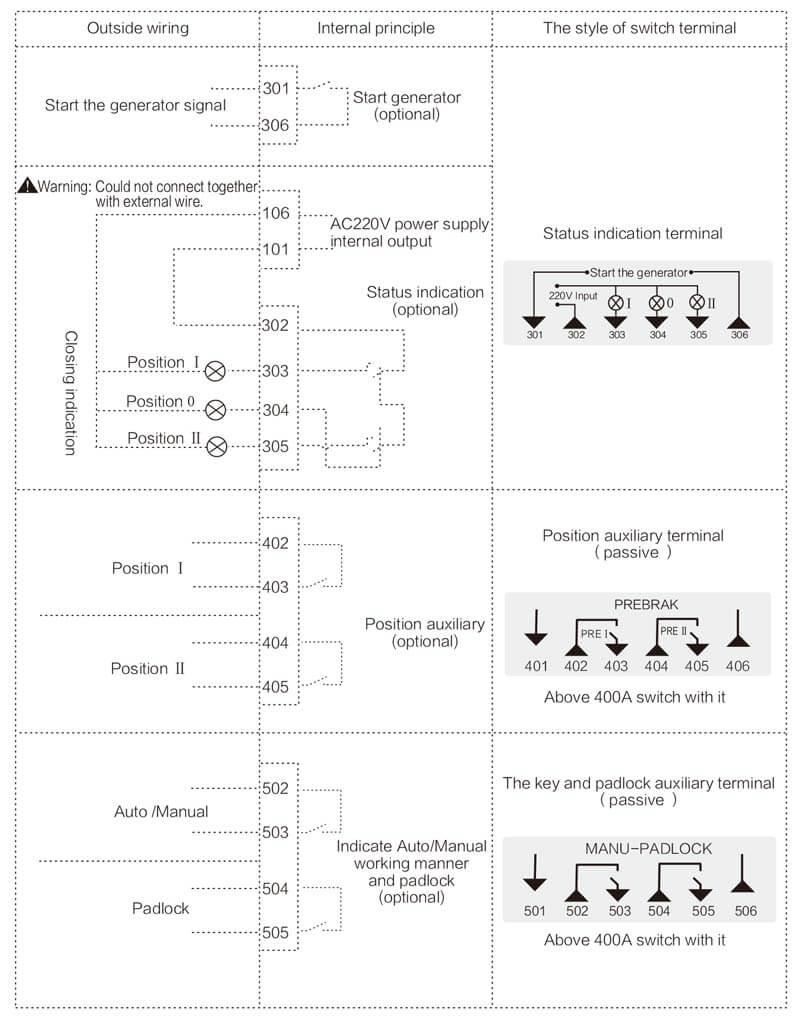

1. The primary wiring diagram to see the picture 3.

2. The control power is derived from normal power, emergency power cand N phases.

3. Ⅰ andⅡ line control power AC220V connected with terminal 102~103,104~105 respectively, 102 and 104 are normal power and emergency power live line respective.

4. Terminal 101,106 are act as signal lamp to control the power supply. Note:101 and 106 couldn't be connected with any other lines.

5. When above (under) input line, under (above) terminalⅠand Ⅱ line A, B, C phases will be connected with copper lines or lines acting as output.

1. Connect the normal power (Ⅰ),emergency power(Ⅱ) to the corresponding copper bar respectively;

① Automatic debugging

Normal power supply with electric,emergency power supply with Electric,switchⅠline switch on

Normal power supply without electric,emergency power supply with electric,switch Ⅱswitch on

Normal power supply with electric,switchⅠ line switch on

(Refer to the switch panel white indicating arrowhead)

② Remote debugging

Press the bush button SB1,then the switchⅠline switch on

Press bush button SB2,then the switch Ⅱ line switch on

③ Automatic/Remote(Manual)debugging

When dial the function selection switch to the automatic position: the switch should act as the ① item required

When dial the function selection switch to the remote (manual) position, the switch should act as the ② item required

2. When the switch is in the position of switch onⅠline or Ⅱ line,the signal lamp on the panel should indicate correspondingly;

3. After finished the debugging,close the power supply firstly,and transfer the switch to the "0" position by handle. (Middle position,refer to the switch panel white indicating arrowhead).

From June 6 to 9, 2023, the 48th Moscow International Power Electronics Exhibition (ELEKTRO) Pavilion opened its doors to the public, and One Two Thre...

Exhibition previewTime flies, after three years of anti-epidemic efforts, remarkable results have been achieved. This year, 2023, trade flows will vas...

First of all, Schneider's low-voltage products include circuit breakers, switches, contactors, relays, etc., which are basically world famous brands.S...

In the design of a dual power transfer switch, the most important is the current control module (TCM), because the current is not strong enough to mee...

GET A QUOTE